I am delighted to be able to address the industry and its people that drive East and West midlands forward, particularly at a time like this.

Let me first acknowledge the brilliant set of entries we have had this year and also thank our judges. My warmest congratulations to our winners.

May I also thank our sponsors for their support during these challenging times.

This time last year was different…was it not? Here we are a year later and what a different world we live in. A global pandemic, BREXT, the challenge of our generation to get to Net Zero Carbon to save our planet and deep and meaningful questions about racial and other inequalities following the events in the US.

Despite these challenges, we’ve kept sites going and reimagined the way we work…whether it’s embracing zoom and teams for communications, redesigning operations to make our sites Corvid safe and deploying COVID cops, rewiring supply chains to make them more resilient, deeply questioning old habits like driving and flying everywhere and throwing up Nightingale hospitals.

As a region, we are well placed.

Firstly, there is huge investment going in with major infrastructure programmes such as HS2, Roads, Rail, Utilities and Green Recovery…and on the back of that will follow the investment into the built environment…add to that Coventry City of Culture and 2022 Commonwealth Games.

Secondly, we have a tremendous talent pool operating out of some world class organisations be they in manufacturing, client, consultancy, construction or academic institutions.

I hope as a collective we will be determined and driven, and look to leave a positive legacy on this period of lockdown…our challenge is to seize the moment and change our sector and region forever. Indeed, as the government would put it, to build back better.

CE Midlands will continue to play a vital role in supporting our members, driving the right debates and enabling growth, innovation and productivity in our region through our hubs, clubs and leadership dinners and celebrating and recognising our fantastic projects and people.

Thank you all for your continued support, good luck and wish you all a prosperous and safe new year ahead.

Uma Shanker, Chair CE Midlands

A thought leadership piece by Martyn Jones.

A long-standing and fundamental weakness of our industry is its deliberate separation of design and construction. This has adversely affected our processes and culture since the emergence of the General Contractor approach to construction at the beginning of the 19 Century.

During the past 150 years or so we have been trying to stitch these two functions back together again through a range of procurement routes including Design and Build, Prime Contracting, the two main Management Approaches, and more collaborative approaches such as Partnering and SCM, but without achieving much in the way of universal success.

CESW’s Procurement and Productivity Theme Group provides us with thought leadership on the effectiveness of different procurement options in reconciling Purpose and Profit, including the very commonly used Design and Build. But, as set out in our guide, Outcome Led Procurement: A common sense approach to construction procurement, design and construction are rarely seamless in Design and Build.

As explained in the guide, when tendering, contractors are rarely given the opportunity to understand the design as it exists at that time (usually incomplete and poorly coordinated). Only after selection can the contractor justify spending the necessary time to fully understand the design and how it will function, plan how it can be constructed and creatively engage with the appropriate specialist contractors and suppliers.

But hang on, by this stage the contractor will have committed to a price to complete the project. Not surprisingly, price will then be a major factor in how the main contractors select the specialist and trade contractors and suppliers as their own margins will depend on a selection strategy that delivers the project for less than the price already quoted to the client.

In turn, the specialist and trade contractors have to price their inputs before they have an opportunity to fully understand what they are pricing and we end up in the situation where all the contractors don’t fully understand the client’s desired project outcomes or the risks involved and how they are priced and managed.

This results in the design and construction process becoming a battleground to safeguard profits and offload risks rather being a well-planned, supportive project environment with the purpose of adding value for the client and providing contractors with fair and appropriate profit for their efforts.

The Two Stage Open Book model offers an alternative approach that sees the client invite prospective team members for a single project or from a framework to bid for a project based on an outline brief and cost benchmark. A number of contractors and consultant teams compete for the contract in a first stage with bidders being chosen based on their capacity, capability, stability, experience, strength of their supply chain, and fee (profit plus company overhead).

In the second stage of the process, the successful contractor and consultant team are appointed to work up a proposal on the basis of an open book cost that meets or even exceeds the client’s stated desired outcomes and cost benchmark.

This Two-Stage Open Book approach provides the opportunity for clients to work earlier with a single integrated team, to interrogate design, cost and risk issues ahead of a start on site at the end of the second stage. This systematic approach to early contractor and specialist contractor engagement provides for more certainty in relation to design information, a more thorough identification and management of risk, and opens up opportunities for creativity and innovation.

As well an opportunity to build greater mutual understanding of both the design and the planning of the construction process, the second stage can also be used to create an environment and culture conducive to the application of the Constructing Excellence principles: Procuring for outcomes and value, increased standardisation and pre-manufactured content, digitally enabled and integrated teams working collaboratively with aligned commercial arrangements.

So, why aren’t more clients using this approach? One popular view amongst many clients and their advisers is that it’s more expensive than simply getting contractors to price for construction of the project through Single-Stage procurement. Yes, Single-Stage requires less input from clients and their consultant advisers and is “easier”, but no, it doesn’t follow that the resulting outturn construction cost will be higher in a Two-Stage approach especially in light of the uncertainties involved in the Single-Stage approach.

When we are busy, our mental health is put on the back burner. This is partly due to mental health’s supposed imperceptible nature. The construction industry has always presented one of the busiest and most dynamic work environments from project initiation to project completion.

All facets of the industry’s complex system have massive challenges as industry professionals and other stakeholders battle to ensure key performance indicators are delivered, whether time, cost or quality.

Unfortunately, mental health issues feed on our inability to keep an eye on our personal wellbeing. Most people are first drawn to the concept of their mental health during some form of crisis or deterioration. Understandably, friends, family and loved ones will jump at the opportunity to offer support in times of crisis.

They can only offer this support when there are visible signs of distress and this is where mental health presents the biggest challenge. Poor mental health does not show many explicit symptoms and is even more invisible when people are preoccupied especially during busy periods at work.

Construction employees (whether based in the office or on site) spend a considerable amount of time at work and this is where they are also put under immense pressure. As such, the workplace offers an opportunity for us to support one another. More importantly, the work environment offers an opportunity for our attention to be drawn to some of the least explicit symptoms of poor mental health e.g. presenteeism.

Constructing Excellence in collaboration with our partners have thus initiated a process of supporting the industry’s stakeholders particularly on the matter of improving mental health. We present this ‘how-to-guide’ to help all in the supply chain and at all levels.

This includes prompting us of some of the subtle tell-tale signs of deteriorating mental health. We believe everyone in the industry should have equal access to mental support and as such we implore all employers (large, medium, small and micro) to spare no expense in protecting their most valuable asset; PEOPLE.

Introduction by Emmanuel Aboagye-Nimo.

The Constructing Excellence Procurement Group have been looking at the key outcomes and lessons learnt from some of the trailblazing projects and programmes that have used collaborative procurement. Considering how the benefits have been realised across the project and its operational performance.

Each case study covers the reasons for the novel approach, the differences from traditional approaches and views from the client and supply chain. The case studies clearly describe the key benefits, the main challenges and the lessons learnt as well as exemplify how collaboration and effective use of technology can deliver better outcomes, faster delivery and lower environmental impacts.

CLICK HERE TO VIEW AND DOWNLOAD CASE STUDY PDF

A Thought Leadership piece by Martyn Jones

Did the authors of the Rethinking Construction report, published in 1998, take sufficient account of the specificities of construction when advocating a Lean form of Supply Chain Management (LSCM)? Were the recommendations of the Egan Task Force based too much on the success of SCM in a resurgent, process-based UK automotive industry?

The members of the Egan Task force were greatly influenced by the radical changes and improvements seen in other industries, particularly the success of Lean Supply Chain Management (LSCM) in the automotive industry. This meant that the Lean form of Supply Chain Management came to dominate thinking in the procurement and management of construction supply chains.

The Egan report was both forthright in its criticism of the industry and radical in its proposals for change. At that time, it was the most explicit presentation of the key features of the emerging techno-economic paradigm to construction. Many in construction found it excitingly seductive too as it seemed to address our longstanding weaknesses and open up opportunities to improve our performance in relation to a range of outcomes including quality, productivity, and health and safety.

The focus was on greater customer focus and more collaborative inter-organisational relationships across our supply chains to achieve more profitable outcomes and competitive advantage for all parties in the chain. It prescribed the building of highly transparent, trusting and long-term relationships between buyers and suppliers to create a physically and socially efficient value chain through the reduction of waste in processes and/or an increase in responsiveness and greater collaboration in product delivery.

But here’s the question? Given the dominance of LSCM thinking, its success in other industries such as the automotive industry, and given the opinion of many in construction that it was a way to tackle many of construction’s weaknesses, why has it proven – with a few notable exceptions such as the supermarket building programmes of the 1990s and 2000s – to be so troublesome to implement and sustain in much of construction?

One of the reasons is that Egan’s report (and indeed the whole approach) is not without criticisms. It was seen by some as being too dominated by big organisations – particularly regular and experienced clients with large and frequent pipelines of demand for construction products and services. It was based on a LSCM approach that was more suited to process-based industries and without any discussion of the alternative – the Agile approach to Supply Chain Management – which could be seen as more appropriate for project-based construction.

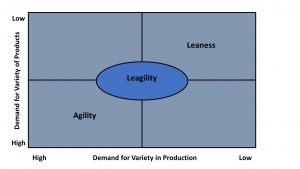

So back in 1998, did Egan invite us to back the wrong horse in the SCM Stakes? Was there another more appropriate runner and rider in the paddock: The Agile approach to SCM (ASCM)? The proponents of this approach argue that LSCM only makes sense under certain circumstances: where demand is predictable, the requirement for variety is low, and volume is high. They argue that an alternative is needed in unpredictable, volatile, highly customised and low market volumes – as in the case in most of the construction market

As professor Martin Christopher argued back in 2000, “There are certain conditions where a Lean approach makes sense … the problems arise when we attempt to implant the philosophy into situations where demand is less predictable [and] requirements for variety is high …[As a result many] firms have been misguided in their attempts to adopt a lean model in conditions where it is not suited”.

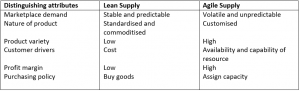

Where demand is volatile and variable, as in much of construction, the elimination of waste is a lower priority than responding to the needs of dynamic markets. Such markets require innovative and market-responsive (or Agile) Supply Chain Management (ASCM) approaches supported by higher margins as shown in the following table.

An examination of the table suggests that at best, it is only those parts of the construction market where the nature of construction spend is regular and ongoing and the relationships between buyers and suppliers are continuous and long-term that are able to fully adopt and sustain LSCM. Where irregular customers require high quality, complex and highly customised products with high-information and value-adding content that require the mobilisation of scarce competencies and the synthesis of diverse technologies then agility is more appropriate.

Agile is also now being seen as more responsive to social and environmental issues, more accommodating of change and uncertainty, and intra- and inter-enterprise integration. Given the necessary tools and support, agile teams, sustained through regular intervals or pauses for fine-tuning of behaviours, can be trusted and empowered to creatively accomplish project goals.

So, what’s best for your supply chains? Lean or Agile? Lean techniques are designed to improve predictable or repeatable actions while Agile works better for innovation projects and original creativity, which are not so easy to manage in a repeatable way. This means that the choice of approach very much depends on the nature of your supply chains and more specifically the volume and frequency of your workflow.

For example, if you are making greater use of the offsite manufacture of standardised components and processes then a Lean approach may suit you best. If you are seeking creativity to tackle say carbon reduction, then an Agile approach may be more appropriate.

And it might not be a case of either/or. You might think about mobilising both Lean and Agile approaches in different parts of your development process and supply chains, with say Agile being dominant upstream to customers and Lean being applied downstream with key and frequently used specialist suppliers. This synergistic blend of Leaness and Agility has given rise to a new form of Supply Chain Management – Leagility.

What can we draw from this? The form of SCM used is very much dependent on context and that collaboration based on trust is essential to the success of Lean, Agile and Leagility approaches. Construction’s customers often procure more on the basis of cost rather than the capability of resources, whilst expecting their suppliers to operate with agility but on lean margins.

So here we all are again in lockdown. Thankfully, the Prime Minister, Boris Johnson, recognised the importance of the UK construction industry in his speech when introducing the latest set of rules and regulations. For our sites it is ‘business as usual’ with the rest of us confined to our homes again. I feel very confident however that thanks to the sterling work of the Construction Leadership Council once again the sector will prove how adept we are with dealing with a crisis and assist the nation through this period of uncertainty.

For CE Midlands, our works seems to grow and grow as the need for collaborative working increases with clients looking for innovative solutions to maintain their building programmes. Our work with Nottingham Trent University continues at pace and we were able to provide an update on the Clients’ Commitments Best Practice Guide at the hugely successful Construction Summit on 5th November 2020. At the Summit we were delighted to welcome Andrew Stephenson MP, Minister of State for HS2, to deliver the keynote presentation and this may be viewed by visiting our brand new web site, along with all the other excellent speeches, on our brand new web site at www.cemidlands.org. Our grateful thanks go to Shakespeare Martineau for generously sponsoring the online summit and providing such a thought-provoking presentation that may also be viewed on our new web site.

In addition to Andrew’s keynote presentation and Richard Whittaker and Stuart Grabham updating the guide, excellent presentations followed from Simon Rawlinson of the Construction Leadership Council on the Roadmap to Recovery, Vince Kesterton of Interserve on the building of the Birmingham Nightingale Hospital with all the best practice examples that could and should find their way into everyday behaviour, and Simon Delahunty-Forrest in unveiling the Birmingham City Centre 2040 Future Plan. However I have to say I was most proud of the presentations given by Paul Chatwin, Amrit Sagoo and Noel Street as they unveiled our ‘How to Guide to Mental Health and Wellbeing’, ‘How to Guide to Best Practice Procurement’ and links with the Grid respectively. The hours and hours of effort provided by our members throughout our network of Theme Groups came to fruition and we owe them a huge debt of gratitude. Details of all these new documents again may be found on our new web site.

Our regular Friday webinars continue, although there has been a slight downturn in viewers which is disappointing. Please do support our November and December webinars as we have an interesting line-up of speakers and topics including this coming Friday 13th November 2020 when Steve Clarke covers the all-important issue of ‘getting more for less’ which never seems to go away and is particularly critical during these troubled times. Further topics include required skills for MMC, the Building Safety Bill and of course our eagerly awaited monthly ‘State of the Nation’ sessions.

We have added to our series of podcasts when I interviewed Suzannah Nicholl, Chief Executive of Build UK, so please do listen to that when you have a spare twenty minutes. It may be found by visiting: https://audioboom.com/posts/7719647-suzannah-nichol-mbe-chief-executive-of-build-uk

The big news since our last newsletter however is a complete turnaround in terms of how we intend to run our 2020 Built Environment Awards by taking them online. The ceremony will take place on Friday 4th December at 12.00pm East Midlands and 2.00pm West Midlands and we hope that all members and supporters will tune in to see who has been successful and help celebrate best practice across the region. As it’s taking place online and during the afternoon rather than make it a ‘black tie’ event we’ve decided to make it ‘loud & proud’ and would ask you to watch in your loudest shirts and ensure you use social media throughout the event to publicise both yourself and the event – let’s go viral! Details of how to book may be found elsewhere within this newsletter.

Finally, I would like to thank the increasing number of people actively involved in CE Midlands with the results previously outlined apparent across the region. We continue to be the ‘driving force’ for the improvement agenda across the Midlands construction sector and if you are not yet actively involved please do so now!

ANDREW CARPENTER, Chief Executive CE Midlands

sponsored by

sponsored by

We had an excellent Summit this year with some exemplary presentations

If you would like to watch or rewatch the recording of this online event or see the individual presentations as PDF please CLICK HERE

List of Speakers

Welcome & Introduction: Uma Shanker, Chair CE Midlands

Keynote Presentation: Andrew Stephenson MP, Minister of State for HS2

Andrew Stephenson was appointed Minister of State at the Department for Transport on 13 February 2020.

He was previously Minister of State at the Foreign and Commonwealth Office and the Department for International Development from 25 July 2019 to 13 February 2020. He was first elected as Conservative MP for Pendle in May 2010.

He was a Parliamentary Under Secretary of State at the Department for Business, Energy and Industrial Strategy from 4 April 2019 to 25 July 2019. He was also a Government Whip, Lord Commissioner of HM Treasury, from January 2018 to April 2019, and served as an Assistant Government Whip from June 2017 to January 2018.

As Minister of State Andrew Stephenson has responsibility for: HS2, Northern Powerhouse Rail, Transpennine route upgrade, Skills

The CLC’s Roadmap to Recovery: Simon Rawlinson, Arcadis

Back in June a task group led by the Construction Leadership Council (CLC) launched the construction sector’s recovery plan.

Simon Rawlinson, a member of the CLC Task Group, highlights how we can all get involved.

“The plan has three main aims. Firstly, it sets out to support the widest possible restart of work consistent with safety guidelines – maximising employment across the supply chain.

Secondly, it aims to reset the work pipeline – combining measures to increase demand for construction with steps to improve productivity, safety and the professionalism of the sector.

Finally, the plan must drive the reinvention of the way that we work – consistent with the priorities set out in the construction sector deal. This will involve wider adoption of the digital and manufacturing technologies, together with new practice in procurement and project management to deliver better value and whole life performance.

For businesses like Arcadis, that have been investing in a digital and product-based future, this is confirmation that our long-term planning will position us well for the other side of the pandemic.”

Nightingale Hospital, Birmingham Case Study: Vince Kesterton, Interserve

This was an emergency facility, designed to increase the capacity in the Midlands region and more specifically for the UHB Trust. The initial brief was to create a minimum of 4000 beds in 11 Halls at the NEC.

The initial Phase was to provide 500 beds in 9 days. This increased in number as the scope changed and there was a requirement for a 100 bed ICU in Hall 8. Phase 1 became 804 beds, together with X-ray rooms, ultrasound rooms, dirty utilities, staff and patient toilets, all fully pumped to the outside, fully piped medigas, back-up generators and UPS.

Phase 2a was an additional 484 beds creating a total of 1288 beds, and included similar additional facilities. This was delivered for two weeks after the delivery of phase 1 in 9 days.

In addition to the beds and all associated ancillary rooms, Interserve’s contract included an Ambulance drop off facility, a Mortuary, a drive through Covid testing centre and a Covid referral doctor’s surgery based of 36 consulting rooms and all the ancillary rooms.

Sponsors Address: Ian Griffiths, Partner at Shakespeare Martineau

Theme Group Presentations

The Clients’ Commitment Best Practice Guide: Richard Whittaker, Citizen Housing

The ‘How to Guide to Mental Health & Wellbeing’: Paul Chatwin, Cundall

The ‘How to guide to Best Practice Procurement’: Dr Amrit Sagoo

Innovation and Sustainabilty and an introduction to ‘The Grid’: Noel Street, 3D Reid

Our Future City Plan – Central Birmingham 2040: Simon Delahunty-Forrest, Birmingham City Council

The plan contains a set of principles that will guide investment in transport so that it is able to serve a future Birmingham that is home to more people and that is a better environment in which to live and work for everyone irrespective of age, disability or income.

These measures are designed to:

-

- Reduce transport’s damaging impact on the environment, supporting Birmingham’s commitment to becoming a carbon neutral city by 2030

- Eliminate road danger particularly in residential areas

- Connect people with new job and training opportunities

- Reconnect communities by prioritising people over cars

- Revitalise the city centre and local centres.

Closing remarks: Andrew Carpenter, Chief Executive CE Midlands

The UK Government has announced new English developments will be required to demonstrate a 10% increase in biodiversity on or near development sites from 2021.

Nottingham Trent University is working on an ERDF funded “BIM for Biodiversity Net Gains” project.

Based on the Biodiversity Metric 2.0 Beta, we are developing a Building Information Model (BIM) toolkit and case study measuring and visualising options for biodiversity losses and gains.

We would like businesses from across the construction sector to complete a short research survey – https://forms.gle/mEbquXf5STyUVu9T8.

Results of the survey will be discussed with an industry focus group.

There will be a MS TEAMS focus group meeting 10am-11am on the 26th November 2020 to discuss the survey results.

Dr Yangang Xing (Yan), BSc, MSc, PhD, MCIBSE, FHEA

Senior Lecturer (Construction Technology and Building Engineering Services)

School of Architecture, Design and the Built Environment

Suzannah Nichol MBE chats to Andrew Carpenter about the moment the idea of working in the construction came to her, setting up Build UK, her love for outdoor activities, achieving her MBE honours and how the industry has handled the Coronavirus pandemic.

CLICK HERE to listen now